Measuring tapes are one of those humble yet indispensable tools found in almost every household and workshop. From professional carpenters and engineers to weekend DIY hobbyists, everyone relies on them for quick, accurate measurements. Yet, despite their near-universal use, there’s one small feature that continues to puzzle — and even frustrate — many people: the loose, wobbly metal tip at the end of the tape.

It rattles. It shifts. It feels like it shouldn’t be that way. Some users even try to “fix” it by tightening the rivets, only to discover that their once-accurate tape now gives incorrect readings. The truth is that this little piece of “looseness” is a stroke of engineering genius — one that ensures your measurements are precise whether you’re working inside a frame or along the edge of a surface.

Let’s unravel this quiet marvel of design.

The Common Misconception: “My Measuring Tape Is Broken!”

At first glance, the loose tip looks like a sign of cheap manufacturing or wear and tear. After all, tools are supposed to feel solid, not rattly. It’s natural to assume that movement in a precision tool equals inaccuracy.

So, when users pick up a new measuring tape and notice the tip sliding back and forth by a millimeter or two, many believe it’s a defect. Some even go so far as to hammer the rivets tight, thinking they’re “fixing” the problem.

What they don’t realize is that they’re disabling a built-in compensation mechanism — a design detail that’s been meticulously calculated to ensure measurements remain accurate in both pushing and pulling scenarios.

In short, that loose tip is not a flaw. It’s intentional.

The Genius Behind the Design

To understand why this wobble exists, we have to look at how measuring tapes are used in different situations.

When you measure something from the outside (say, the length of a table), you hook the metal tip over the far edge of the object and pull the tape taut.

When you measure something from the inside (for example, the width of a drawer or a window frame), you press the metal tip against the inner edge and push the tape outward.

The problem: The tip itself has thickness — usually around 1/16 of an inch (or roughly 1.5 millimeters). If that thickness weren’t accounted for, every inside measurement would be off by the width of the tip.

To solve this, engineers designed the tip to move back and forth by exactly its own thickness.

- When you hook the tip over an edge and pull, it moves outward, compensating for the metal’s thickness.

- When you press the tip against an inside surface, it slides inward, once again compensating for that same thickness.

This ensures that whether you’re pushing or pulling, the measurement displayed on the tape is the true distance between the two points — no extra math, no guesswork, no hidden error.

It’s simple, elegant, and surprisingly clever.

How It Works: The Physics of Precision

Let’s break this down visually — or imagine it in motion.

- Outside Measurement (Pulling):

You hook the metal tip over the end of a board. When you pull the tape taut, the tip extends slightly outward. The movement (usually 1/16 inch) compensates for the thickness of the metal tip, ensuring the “zero point” starts exactly at the edge of the board. - Inside Measurement (Pushing):

You press the metal tip against a wall or the inside of a window frame. This time, the tip slides inward by that same 1/16 inch, aligning the zero point perfectly against the inner edge.

Without this movement, every inside measurement would be too long, and every outside measurement would be too short.

That small amount of play — so easily mistaken for looseness — is what makes a measuring tape accurate in both situations.

The Engineering Details: Not Just a Wiggle

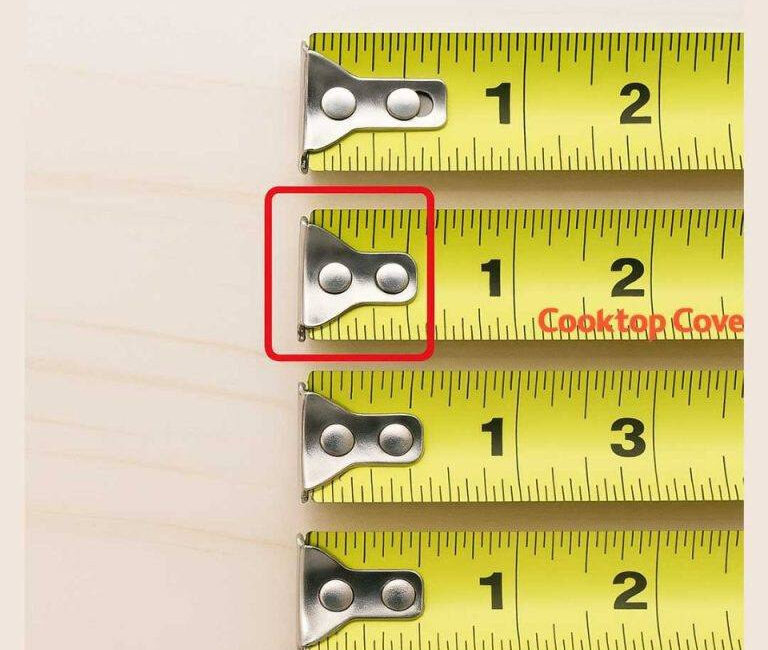

The tip’s motion isn’t random. It’s precisely controlled. The tip is usually attached by two or three rivets through elongated holes, allowing it to slide back and forth within a defined range. The distance of this movement is carefully calibrated during manufacturing to match the thickness of the tip’s metal.

In addition to compensating for thickness, this design helps reduce stress on the tape when it’s hooked or pulled repeatedly. The tiny flex and movement act as a cushion, preventing the tape from tearing or deforming at the end.

So the wobbly tip actually has two functions:

- Measurement accuracy (push/pull compensation).

- Structural durability (shock absorption).

What looks like looseness is actually precision engineering.

A Hidden Bonus: The Tip Doubles as a Marker and Magnet

Beyond its compensatory movement, the metal tip of a measuring tape has a few other clever features that often go unnoticed:

- Serrated edge: The small serrations at the end aren’t decorative. They allow you to mark a surface by scratching it lightly if you don’t have a pencil handy.

- Magnetic tip (on some models): Professional tapes often include a magnet embedded in the tip, allowing you to stick it to metal surfaces or hold it in place when measuring alone.

Each of these features works in harmony with the “loose” design — proof that even the smallest detail of a measuring tape is the result of thoughtful engineering.

What Happens If You “Fix” It

If you’ve ever tightened the rivets or glued the tip to stop the movement, you’ve probably noticed something strange: your tape suddenly starts giving inconsistent readings.

That’s because once the tip can’t move freely, the tape no longer compensates for the thickness difference. Inside measurements become longer than they should be, and outside measurements become shorter.

A locked tip means your tape will only be accurate in one type of measurement, not both. For professionals — carpenters, builders, metalworkers — even a millimeter of error can cause serious problems down the line.

So, the golden rule: If the tip moves slightly, it’s working properly. If it doesn’t move at all, it’s broken.

How to Check if Your Tape Is Accurate

Curious to test your own measuring tape? Here’s a quick way to check its calibration at home:

- Find a flat, hard edge like a table or countertop.

- Hook the tip over the edge and take a measurement to a fixed point.

- Now, press the tip against that same edge and measure again to the same point.

Both measurements should match. If they don’t, your tape’s tip may be bent, dirty, or improperly adjusted.

A small buildup of dust, paint, or rust around the rivets can also affect movement. Cleaning the tip with a soft cloth or a drop of oil can restore smooth operation.

Appreciating the Thought Behind Everyday Tools

The loose tip is a perfect example of how good design often hides in plain sight. It’s easy to overlook because it feels counterintuitive — precision tools, we think, should be rigid. But engineering is rarely about appearances; it’s about function meeting physics.

When you pull that tape measure across a wall or press it into a corner, you’re benefiting from generations of toolmaking refinement — from blacksmiths who made early folding rules to industrial designers who introduced the modern retractable tape in the 20th century.

Every rattle, every spring, every mark on that strip of metal exists for a reason.

Beyond the Loose Tip: What Makes a Good Measuring Tape?

If you’re serious about accuracy or craftsmanship, understanding the anatomy of your tape helps you choose the right one for the job.

- Blade width: A wider blade resists bending and allows for longer “standout” — the distance you can extend the tape before it collapses.

- Coating: Nylon or matte finishes protect markings from wear and glare.

- Locking mechanism: Keeps the blade steady during long measurements.

- Hook strength: The riveted end must move freely but stay firm.

- Spring tension: A good retraction spring provides smooth, controlled recoil without snapping back too fast.

Professional-grade tapes are tested to maintain accuracy under both push and pull conditions, ensuring that the tip movement is always within precise tolerances.

The Lesson: Precision Doesn’t Always Look Perfect

In a world where tightness often equals quality, the measuring tape teaches a subtle lesson: sometimes, a little play is what makes things precise.

That slight clink at the end of your tape is not a flaw — it’s a built-in solution to a centuries-old measurement problem. It’s proof that true craftsmanship lies not in rigidity, but in adaptability.

The next time you hear your measuring tape rattle, smile — it’s not broken. It’s working exactly as it should.

And perhaps that’s the best metaphor for all well-designed tools: the details that seem odd at first are often the ones that make them truly reliable.